Basic Info.

Model NO.

HLCNC-3319

Control

CNC

Automation

Automatic

Precision

High Precision

Application

Granite, Marble

Type for Grinding Machine

Special Grinding Machine

Grinding Method

Wet Grind

Certification

ISO, CE

Tools

Router and Grinder

Guide Rail

Linear Guide

Dimensions of Working Table

3300*1900

Gearing

Rack Gear

Max. Processing Length and Width

3300mm/1900mm

Tools Change

Automatcially

Tools Change Positions

20

Color

Red and Ivory

Vacuum Cup

Included

Stroke(X-Axis)

3300mm

Stroke(Y-Axis)

1950mm

Stroke(Z-Axis)

320mm

Power

7.5kw

Rotating Speed

0-8000rmp

Tool Holder Model

Bt40

Transport Package

Polypropylene Plastics Packing

Specification

5520*320*230

Trademark

Hualong

Origin

Putian, Fujian, China

HS Code

84641010

Production Capacity

50 Pieces/Month

Packaging & Delivery

Package Size

550.00cm * 320.00cm * 230.00cm

Package Gross Weight

5000.000kg

Product Description

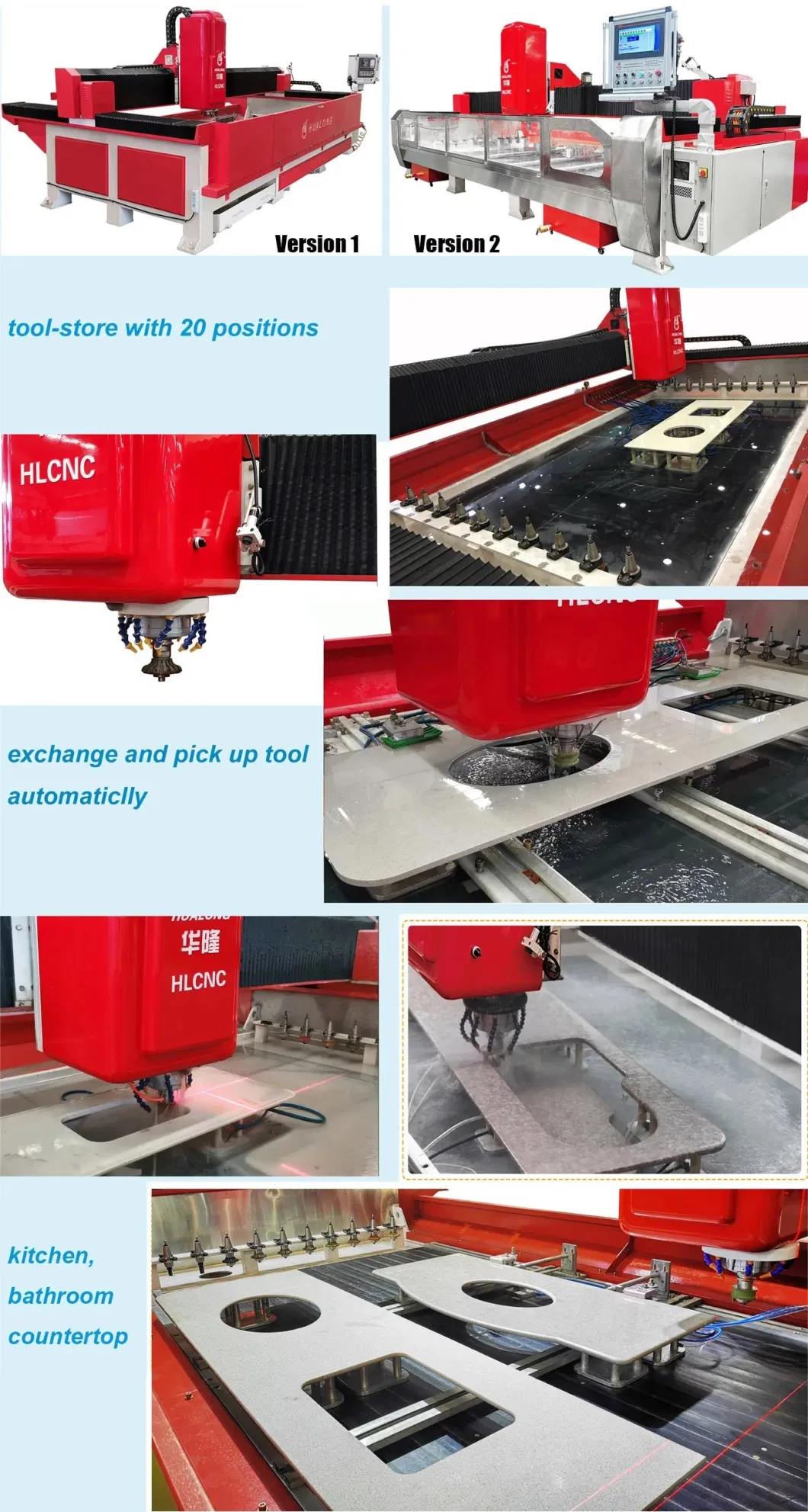

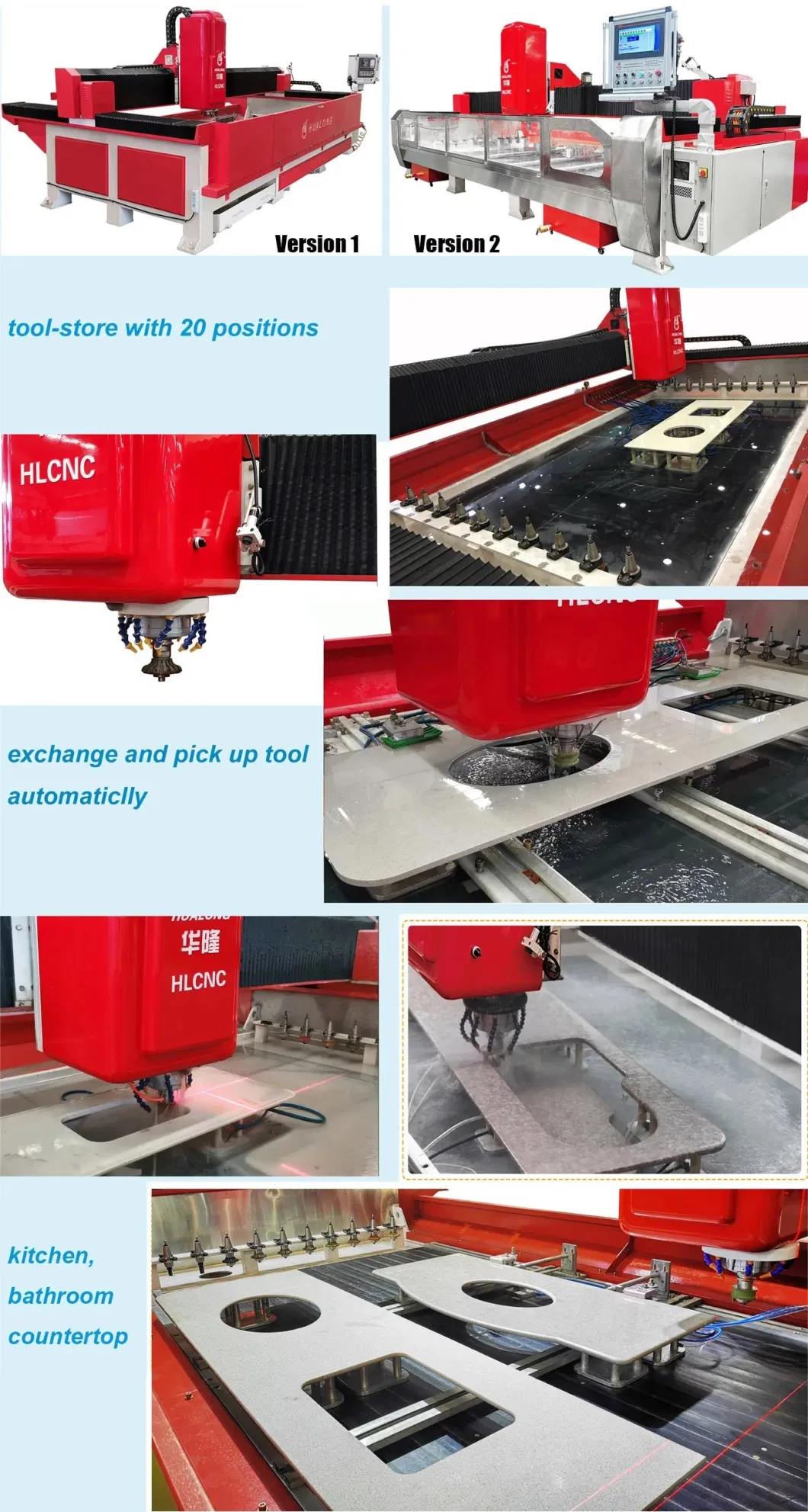

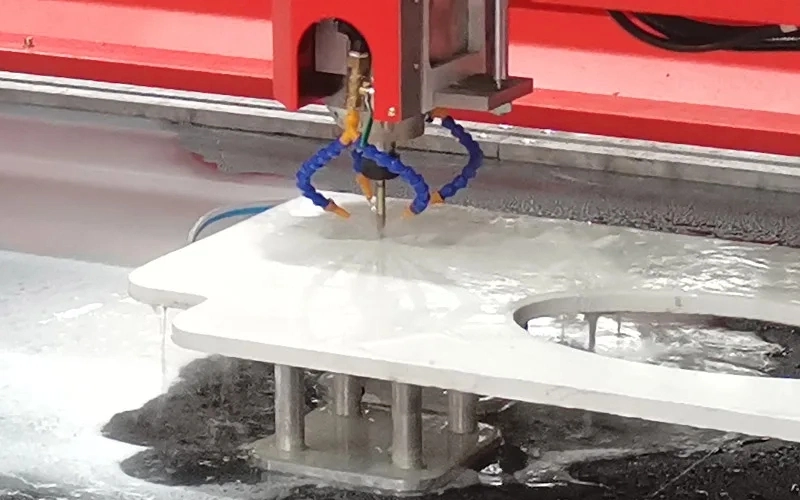

CNC Stone Countertop Processing Center

HLCNC-3319 is a CNC milling and edge polishing centre designed for contouring, cutting and turning with three interpolated axis offering users the possibility of multiple and complex machining operations which would otherwise require several machines. It's suitable for processing all kind of stone slab coutertop, such as kithen countertop, bath countertop, cabinet countertop, bar counter, table, windowsill, door sets etc. Relief engraving like stone background wall relief, European style edging etc. is available too.

| TECHNICAL DATA | ||||

| Model Number | HLCNC-3015 | HLCNC-3319 | HLCNC-1308 | |

| Stroke (X-axis) | mm | 3040 | 3500 | 1340 |

| Stroke (Y-axis) | mm | 1540 | 1950 | 840 |

| Stroke (Z-axis) | mm | 320 | 320 | 320 |

| Power of motor | kw | 7.5 | 7.5 | 7.5 |

| Rotating speed | rpm | 0-8000 | 0-8000 | 0-24000 |

| Tool holder model | BT | 40 | 40 | 40 |

| Tool-store position | nr | 12 | 20 | 11 |

| Workbench dimension | mm | 3000x1500 | 3300x1900 | 1300x800 |

| Gross Weight | kg | 4000 | 5000 | 2500 |

| Demension (L x W x H) | cm | | 553x320x230 | |

Main Features

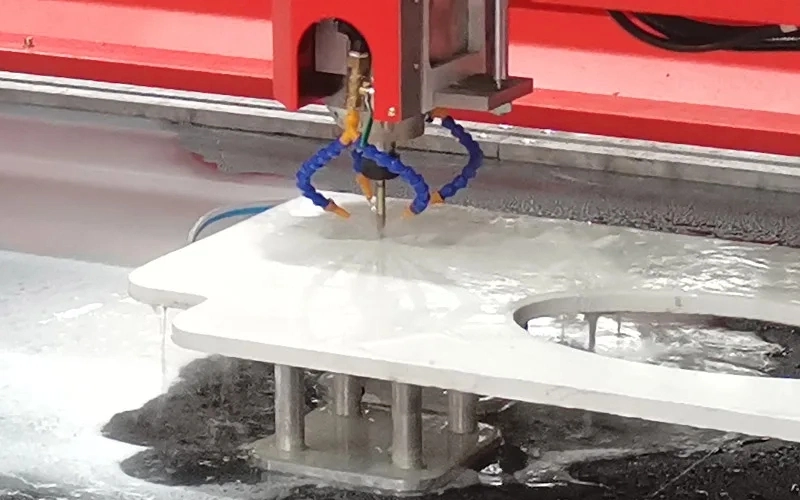

1) Powered by numerical control planning and interfaced with our CAD / CAM software, their automatic tools allow for calibration, milling, carving, honing and polishing slabs continuously and automatically in one go.

2) Bilateral tools-store with 20 stations for automatic tool change

3) Crossbeam and carling adopt Taiwan's Hiwin linear guide to move, which ensure high precision of cutting and long life.

4) X/Y axis with dust colletor,keep machine cleanly,prolong useful-life

5 )3 axis Yaskawa servo driver,high speed, high efficiency, fine cutting without serrated ripple, smooth bottom plane,clear outline.

6) With vacuum cups and aluminum alloy lock to double holding the working pieces, avoiding even little displacement

7) Equipped with USB interface for operator to input and output program conveniently.

8) High speed and low noise.

9) High efficiency and low processing cost.  Engraving module is optional for dual functions

Engraving module is optional for dual functions

If you have any special requirements, just click below and let us know.

If you have any special requirements, just click below and let us know.

2) Bilateral tools-store with 20 stations for automatic tool change

3) Crossbeam and carling adopt Taiwan's Hiwin linear guide to move, which ensure high precision of cutting and long life.

4) X/Y axis with dust colletor,keep machine cleanly,prolong useful-life

5 )3 axis Yaskawa servo driver,high speed, high efficiency, fine cutting without serrated ripple, smooth bottom plane,clear outline.

6) With vacuum cups and aluminum alloy lock to double holding the working pieces, avoiding even little displacement

7) Equipped with USB interface for operator to input and output program conveniently.

8) High speed and low noise.

9) High efficiency and low processing cost.

Sintered Stone Countertop Machining

Control Console

Version 1 Version 2

Control System Brand: Syntec Control System Brand: ESA --- Optional

Original: Taiwan, China Original: Italy